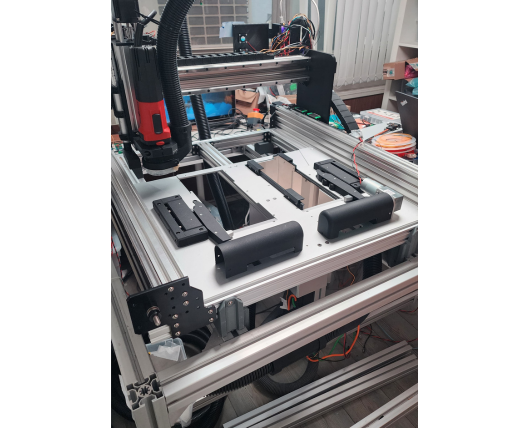

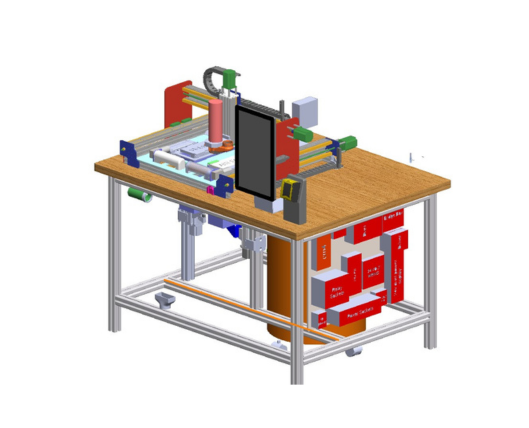

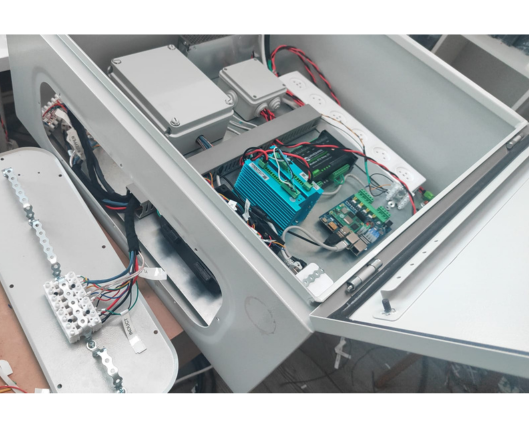

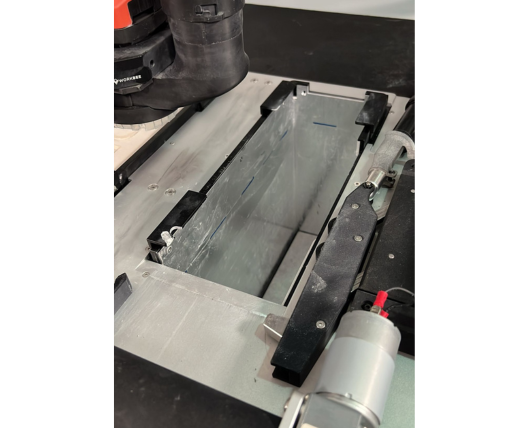

Art-Factory is a fully automated vending machine designed to engrave personalized house signs on stone tablets. The machine offers a seamless user experience: customers approach the kiosk in a shopping mall, enter their family name, choose the stone color and size, complete the payment, and the machine begins the engraving process automatically. The project was developed in collaboration with Israel Amaris, experts in custom vending machine design. While our team handled the hardware and software integration, their team was responsible for the mechanical design and engineering. Together, we delivered a robust, market-ready solution for Darya, a company specializing in house signs.